|

sub2_menu

|

|

The life span of the heating device

UNI-BAR(silicon carbide heating device) is slowly oxidized in the air atmosphere and the silicic acid is formed and the electric resistance is increased which results in deterioration.

The formula for oxidation reaction is as follows:

SiC + 2O2 -----> SiO2 + CO2

A Silicon carbide (SiC) reacts to a dioxygen (O2) in the atmosphere and oxidizes gradually on the surface of a heating device. It forms an insulating material Silicon dioxide(SiO2), and this amount increasing effects on the electric resistance rise.

|

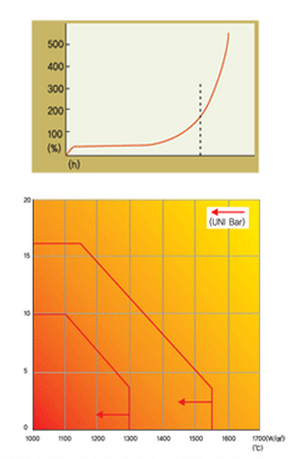

1. Workable Temperature

The life-span will be short when it is used for the higher temperature. When the inside temperature of the furnace is over 1400℃~1600℃, oxidation rate is accelerated which makes the life-span shorter.

Therefore, it’s recommended to keep the surface temperature feasibly lower.

In other words, it’s better to keep the temperature difference small between the inside furnace and the heating device.

2. Surface Load Density

To present the applied electricity strength, a surface load density(W/cm2) is used. It is the electricity per 1 cm2 of heating device surface area of UNI-BAR.

The higher the temperature is, the shorter the lifetime of UNI-BAR is.

The heating device surface temperature is higher when its surface load density is higher than the other even though they have the same incore temperature.

|

|

3. Limitation of Surface Load Density

A category range is limited, therefore we practically use it in the range of 1/2~1/3 surface load.

4. Rating of UNI-BAR

The rating is marked on the end. However, this rated current is following the JIS standard which is keeping 1000℃ for the surface temperature of the heating device in open atmosphere and the surface load density of 15W/cm2. Please aware of applying current on UNI-BAR with this rated current which will be overloading current.

5. to apply current ( intermittent operation and continuous operation)

A continuous operation of an electric furnace makes its lifetime longer than the intermittent operation of it. A silicic acid is formed on the surface of a silicon carbide which is oxidized while using SiC heating device.

This silicic acid grows gradually for a long period of time which results in electric resistance of a heating device.

This silicic acid film sets abnormal expansion and contraction around the crystallization temperature(270 ℃).

If this device is used around this temperature during the intermittent operation, these repeating film distortions accelerate oxidization. Therefore, there are cases for rapid electric resistance increase when the temperature goes down to around the room temperature due to power outage or other reasons.

|

|

|