|

sub2_menu

|

|

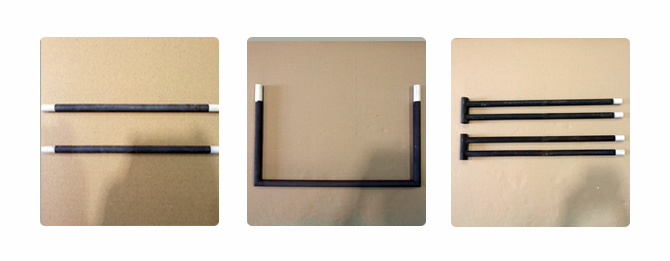

| Uni-Bar(SIC Heater) is a non-metal high temperature heating device made from SiC as its main raw material.

Uni-Bar has the following characteristics: low coefficient of expansion, little deformation, chemical stability, long-life, easy installation, and maintenance.

Uni-Bar can be used for the furnaces with the range of 600℃~1600℃.

It can be used directly without any protection atmosphere in the air atmosphere.

It is used in metallurgy, ceramic, glass, machinery, assaying, semiconductor, science, and research and development.

The usage of it is machine manufacturing, metallurgy, light industry, electronic parts, silicate industry, national defense, science study facility, magnetism material sintering, optical glasses, fluorescence powder, aluminum smelting furnace, casting furnace, metal/non T metal heat treatment, and high frequency magnetism and powder molding.

|

It has high temperature resistant, oxidation resistant, and erosion-resistant. The heat emitting part coating method extends the lifetime of the heating device in various complicate environment. It has high temperature resistant, oxidation resistant, and erosion-resistant. The heat emitting part coating method extends the lifetime of the heating device in various complicate environment.

The recommended maximum atmospheric temperature of the inside of a furnace is 1350 ℃. The recommended maximum atmospheric temperature of the inside of a furnace is 1350 ℃.

|

|

It is a heating device with a spirally grooved surface on the heating part which makes to endure high temperature and keep high corrosion resistance. It is a heating device with a spirally grooved surface on the heating part which makes to endure high temperature and keep high corrosion resistance.

The aluminum film on non-heating part is used for forming a low resistance on its surface when heated. A SCREW UNI-BAR is mainly used for industrial and research furnaces.

|

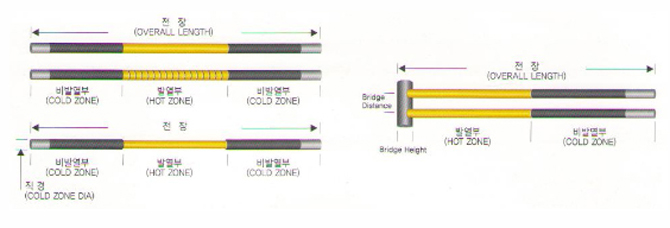

Unit : mm

| |

Diameter Range |

Max. Hot

Zone Length |

Max. Overall

Length |

| UNI-BAR |

10 ~ 45 |

2,000 |

3,000 |

| USD,USD-1,UST |

16 ~ 44 |

2,000 |

3,000 |

| SCREW UNI-BAR |

10 ~ 35 |

1,000 |

1,600 |

| UniTech’s UNI-BAR is a high temperature heating device that the surface temperature can be raised up to 1600℃.

The heat value per unit surface is usually 5 times to maximum 10 times higher than other metal heating devices which makes it economical and eco-friendly heating source.

|

UNI-BAR Max. surface temperature w/service condition UNI-BAR Max. surface temperature w/service condition

Unit : ℃

| Condition |

Air |

Nitrogen

Hydrogen |

Exothermic Gas

Endothermic Gas |

Hydrocarbons |

Vacuum |

| Max. surface temperature |

1,600 |

1,300

1,200 |

1,000~1,400 |

1,250 |

1,300

1,200 |

|

|